Driveway “Any Header” B Series Catalytic Converter

There are two choices for anyone who wants to run a big 2.5" collector header on a OBD2 Honda. Cheat or get a custom catalytic converter. We document a catalytic converter solution for the Honda B Series engine in Civic and Integra chasis that we have used for many vehicles needing to trully pass emisions and is #drivewaybuilt friendly.

The Driveway "Any Header" Catalytic Converter allows easy integration and connection of almost any open market big 2.5" collector sized header and exhaust combination while keeping your EG/EK/DC2 OBD2 compliant with minimal ease.

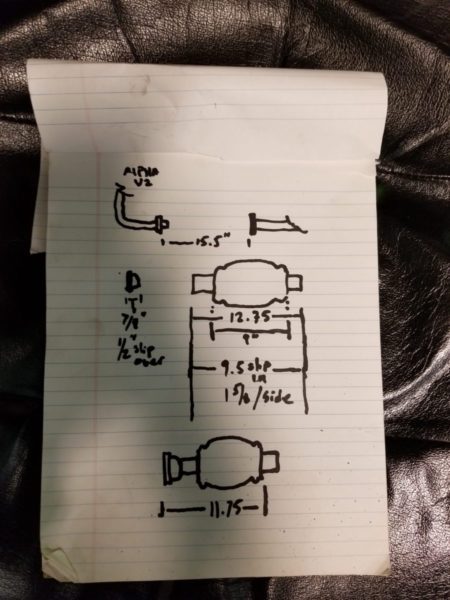

The short body Magnaflow universal catalytic converter allows a final length range of 13.75" to 20+" when combined with an easily sourced "Test Pipe". A bolt together design using a cut to length Blox test pipe ends makes this an easy solution for headers utilizing a 2.5" collector size deemed "Off-Road ONLY". The catalytic converter also retains the traditional catalytic converter appearance for inspection while letting that "Off-Road ONLY" header flow properly.

Design ... Design

1. Measure distance between header collector flange and cat-back flange.

2. Determine end lengths required to mount the Magnaflow catalytic converter.

The Magnaflow universal converter will have an effective 9.5" length.

(Measured distance from Step 1)-9.5" = The total distance required to be made up from cut ends of test pipe.

Assemble to Length

3. Cut ends of Blox test pipe using hacksaw, sawzall, pipe cutter, or any cutting implement available. Insert inside Magnaflow ends.

Cut Blox test pipe collector side between O2 bung and collector flange. Pry Blox name plate off if necessary. Depending on your final length, ends of Magnaflow catalytic converter may need to be cut down.

Total length of both test end cut pieces added = Total Distance Required(measured in Step 2).

4. Test fit to car with collector donut gasket and secondary O2 installed.

Rotate ends to align with collector and cat back flanges. Adjust as necessary to ensure 02 Sensor is clear of body and is pointed at a minimum 10° up from horizontal position. 02 Sensor should be towards the rear of the car as shown.

4. Use exhaust band clamps or u-bolt clamps for 2.25" diameter pipe to secure and seal ends within the converter. Tighten per clamp instructions.

Keep Wrenching !!